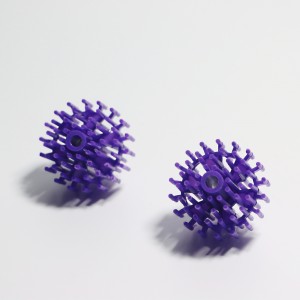

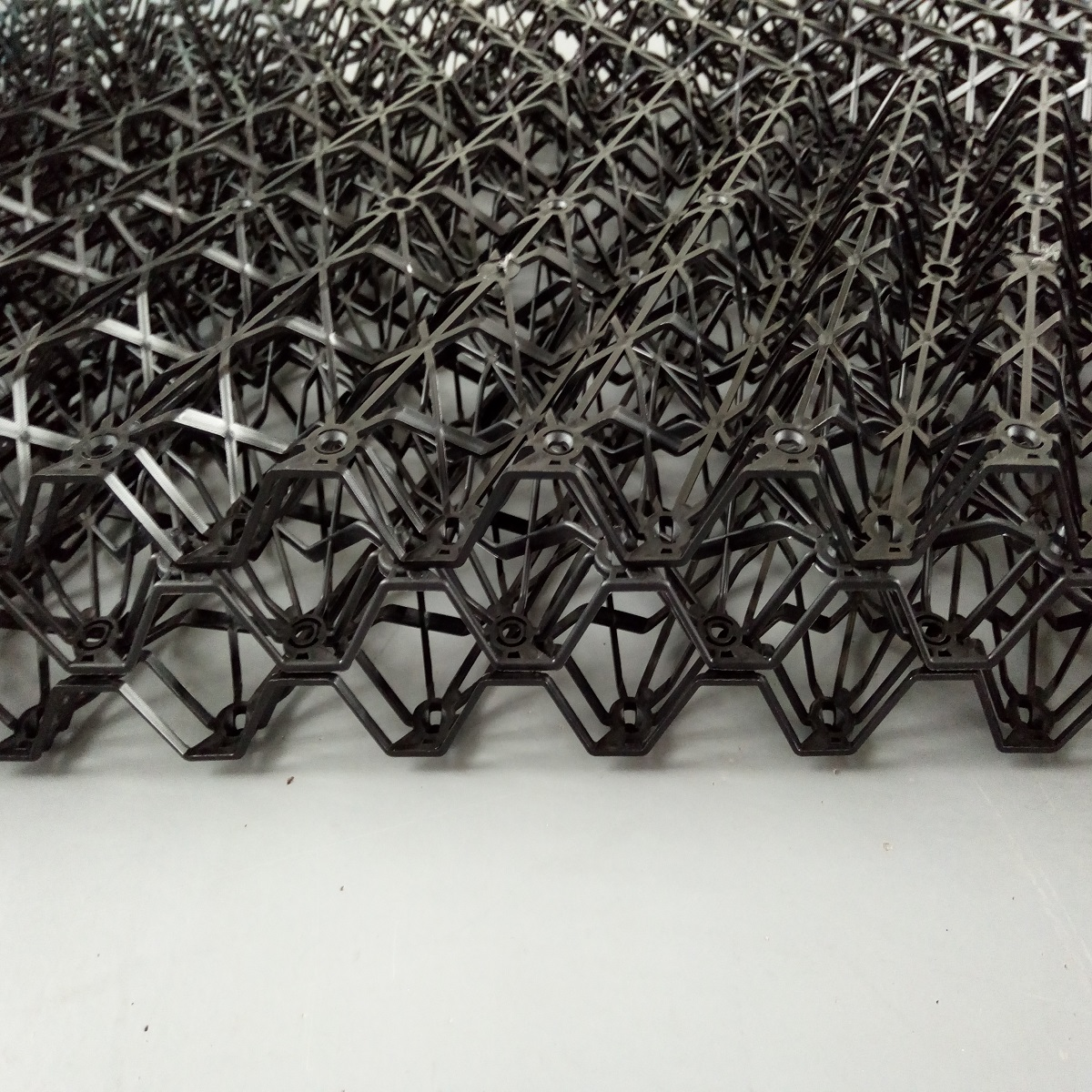

Cooling Tower Fills Splash Fill Wet Net Filler Cooling Filler

Technical Parameter

|

Specification/mm |

910*450 |

Void ration/% |

99 |

|

Liquid-gas ratio |

0.1-0.3L/m³ |

Surface area m²/m³ |

≧120 |

|

Density g/cm³ |

≧0.9 |

VICAT |

≧135 ℃ |

|

Tensile strength |

≧6.5N/mm |

Elongation at break |

100% |

|

Wind resistance under not exceed 2m/s |

10-15 Pa |

Carbon black content |

≧2 |

|

Anti-aging test |

|||

|

Through 200 hours Xenon lamp lighting, No cracks, discoloration, chalking phenomenon, mechanical strength still retains more than 50% |

|||

Working Principle

Horizontal ventilation Mode:

When Exhaust in pig farm passing Fan to Washed filter wall,Exhausts humidity will increase by be spayed and form air & liquid mixing.Partly of Ammonia and dust will be absorb by droplet and fell down the reservoir.Hydrogen sulfide and ammonia and so on will be grasped by Biological bacteria attached on wet net filler module and decomposed. Therefore, Exhaust will be purified.

In order to ensure the activity of biological bacteria, the spray system will automatically adjust PH, spray volume, water replenishment volume and so on based on PH,LF test equipment’s test data. This adjustment keeps Biological bacteria’s Long-term & effective activity

Longitudinal ventilation:

The working principle is same with horizontal ventilation.The biggest difference is air flow direction.Longitudinal ventilation can extend the vertical channel height and increase wet net filler module thickness.

In big pig farm or livestock farm with large displacement,Two mod integrated application will achieve outstanding Deodorizing effect.

- Previous: Multi-layer filter block

- Next: IMTP Ring