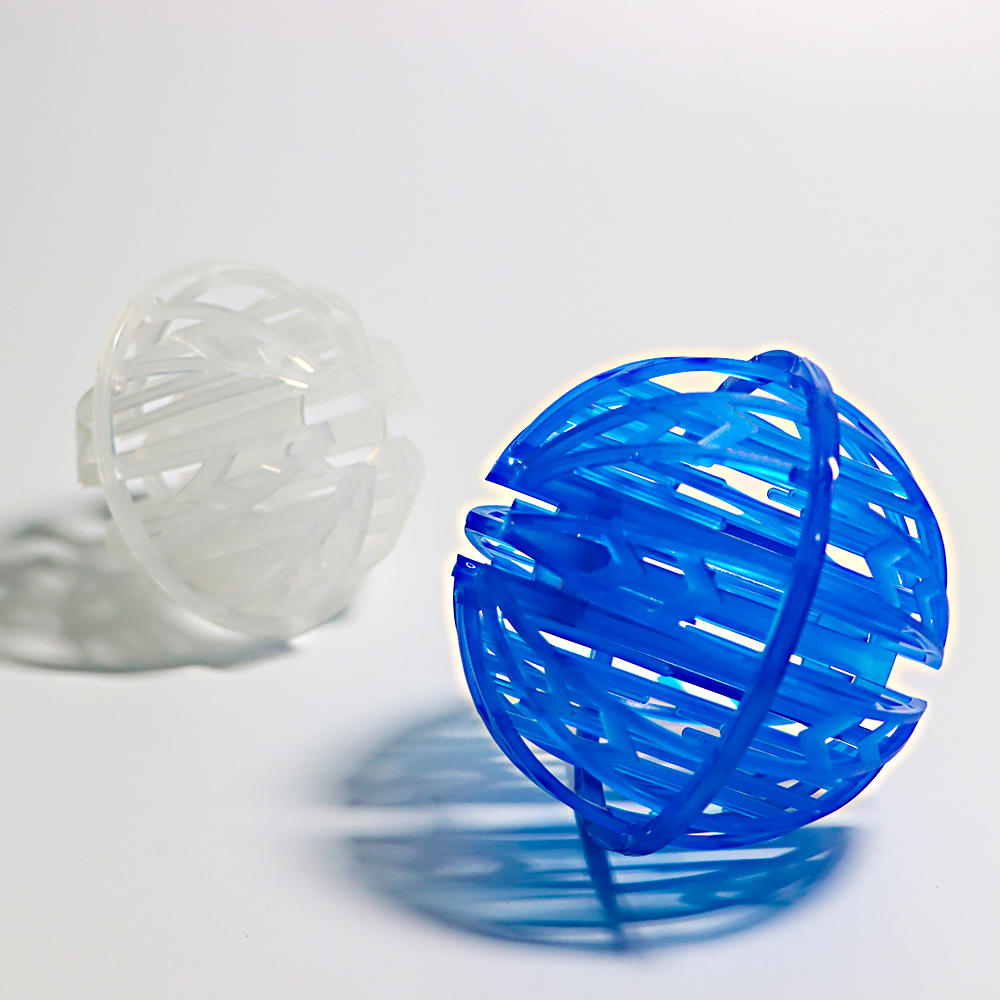

It was invented by Jaeger Tri. Generally speaking, No big surface area is Tri-pack’s biggest advantage. Owing to Tri-pack has no corners and valleys. The result is extraordinarily high scrubbing efficiency while minimizing the amount of media and packing depth required.and prevents dry spots and compression interlock.The distinctive shaping of ribs, struts and drip rods gives Tri-Packs tower packing media superior wetting characteristics, and the ability to maintain uniform liquid distribution throughout the bed.

In the traditional theory of mass transfer, we often think big surface area will increase the mass transfer efficiency. Sometimes, Excess surface area can impede gas/liquid contact and create higher pressure drops,. Finally, it will lead to Packing’s channel blocking.Based on this new understanding, Jaeger had invented Tri-pack.

Basically tri-pack provides maximum surface contract between the gas and the scrubbing liquid by facilitation through continuous formation of droplets by the packed bed. It was recognized best packing in for air stripping,degasifier and scrubber