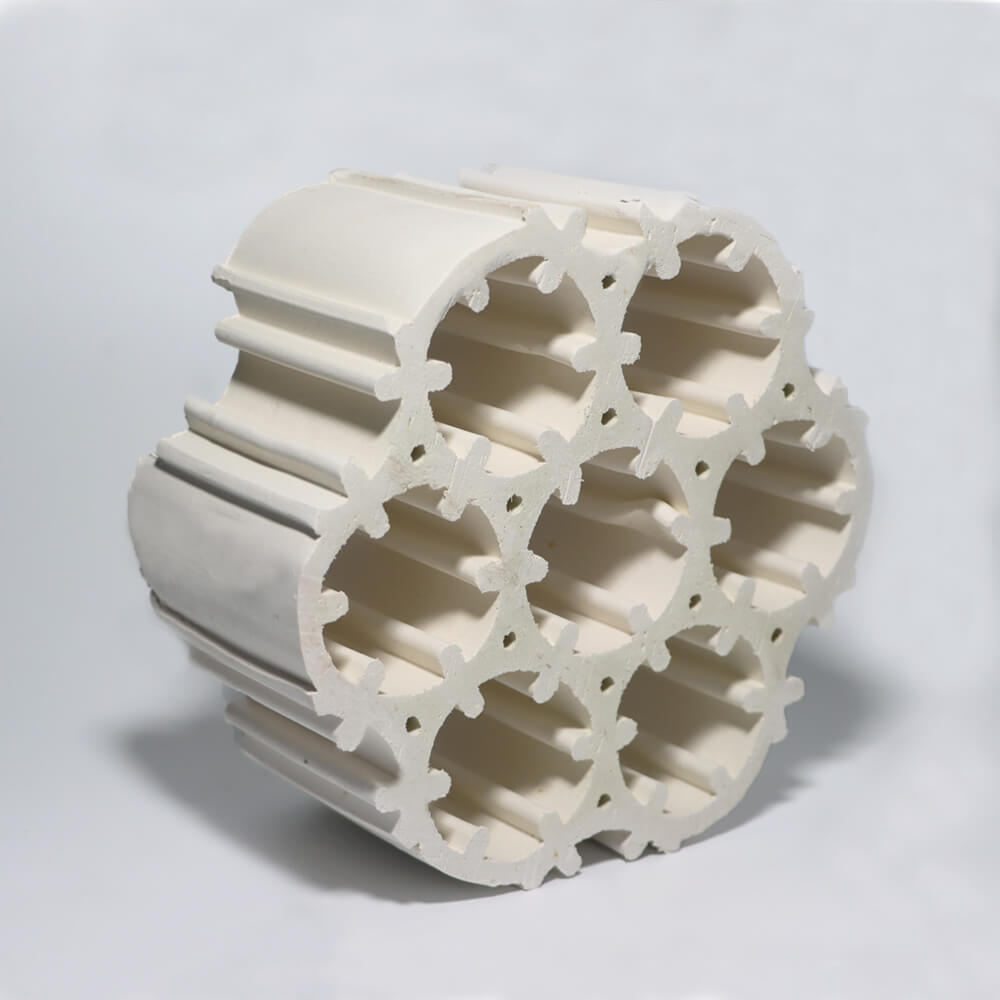

Owing to Ceramic Corrugated plate packing’s weight is very heavy and easy broken, in 1980s ending,our Scientists change clay’s composition to produce Light porcelain packing. Light Porcelian packing surface has many micropores, which can be fully soaked by liquid so as to prolong gas-liquid exchange time. However, If compared with all-ceramic fillers,no matter in terms of compressive strength, water absorption, wettability, maintenance, replacement, production process, etc., the performance of all-porcelain pakcing is much better than that of light porcelain packing. Therefore, On the issue of choosing light porcelain or all porcelain packing, please consider the actual operation enviroment carefully. Generally speaking, Both of them are widely used in the processes of coking desulfurization,washing benzene,naphthalene and ammonia sulfuric acid drying,chemical fertilizer hot water saturation tower,electric power plant tricking water colling tower, absorbing tower and on.